The environmentally-friendly,

economical alternative to

retaining walls

SYSTEM OVERVIEW

Our patented “Greensteep” system is an economical and environmental friendly, mechanically stabilized earth (MSE) steep fill system. The MSE technology was developed in the 1960’s and its use is now rutine. The “Greensteep” system also incorporates an updated 2,000 year old Roman Empire block building technology, with blocks formed using our specially developed machinery, and a vegetative facade that seamlessly blends the structure into the landscape. It requires little or no maintenance and is also resistant to graffiti.

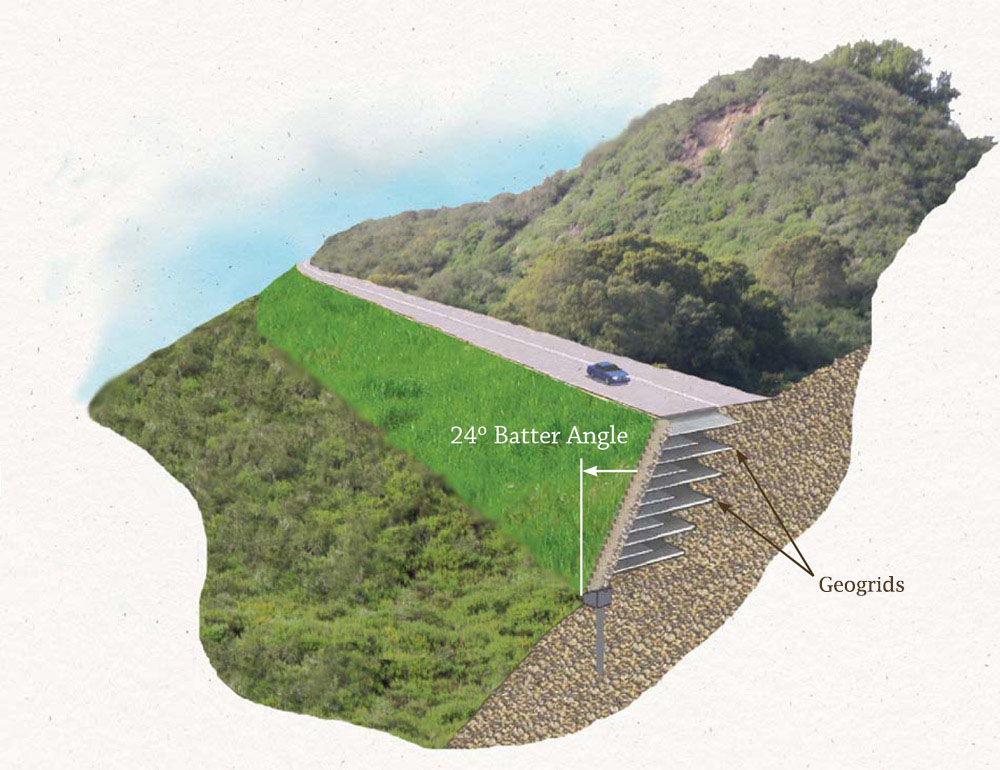

The Greensteep system utilizes rock-like, hard, cement-treated soil blocks that are placed in a near vertical configuration on the exterior face of an earth-filled slope. In comparison with standard retaining walls, there are significant cost savings and the vegetation on the faces of the blocks, radically improves aesthetics.

Costs are reduced by the use of onsite, native soils to create the blocks at the project site, as the amount of material required from suppliers and their transport to the site are drastically reduced. Well-suited for highway construction, lane additions, on-and-off ramps, landslide repairs, building pads and more, the Greensteep system offers unbeatable cost-effectiveness and visual appeal.

INNOVATIVE BUILDING BLOCKS

Greensteep’s innovation begins with its unique block units. These blocks are created by our specially developed 200-ton capacity soil-press that compacts a mixture of native soil and cement into a rigid block. The mixture only requires an ordinary soil, cement, moisture conditioning and the high degree of compaction that is provided by our press. Our own laboratory test results, in addition to published studies, indicate that cement-treated soils can easily attain a compressive strength of 30,000 psf. This translates into rock-like strength that greatly exceeds that required for the safety of the system.

An exterior galvanized-steel, wire-mesh wrap provides additional strength that prevents tension cracking.

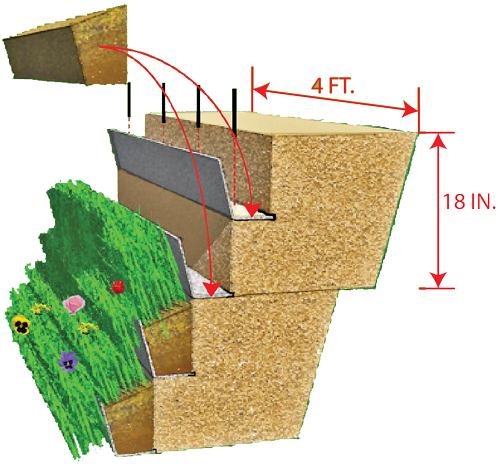

A rectangularly-shaped insert placed at the bottom of the press in conjunction with offsets between the blocks, produces benches that accommodate “L” shaped concrete panels. The panels produce 5” wide and 8” deep, planters (see Figure). The panels are secured in place by being pushed into a notch at the base of each vertical face and pinned to the bench.

Once filled with soil, the planters serve to host vegetation growth on the slope’s exterior face.

SUMMARIZING OUR

GREENSTEEP SYSTEM

We place a mixture of soil and cement in a

200-ton press and compact it to make rock-hard blocks at the project site.

We then stack the blocks on the exterior face of a mechanically stabilized earth (MSE) that has ample geo-grid reinforcement.

Next we place “planters” on the block’s exterior face, to produce 8-inch high and 5-inch wide plant planters. The planters and blocks are then securely connected to the geo-grid reinforcement.

The vegetation then grows!!!

The finished product is not a retaining wall – it is an economical, aesthetically pleasing, “Greensteep” slope.

APPLICATIONS

Reduce the “Concrete Jungle” effect in our metropolitan areas by making these concrete walls go away. Replace them with green slopes like this.

And, let’s do away with these ugly walls that impact our rural scenic landscapes and replace them with green slopes.

Ideal for new and existing highway widening projects.

PATH TO COMMERCIALIZATION

The Greensteep system has concluded an evaluation process under a framework developed by the FHWA called IDEA (Innovations, Development, Enhancement and Advancement) program. The program is administered by the Geo-Institute of the American Society of Civil Engineers (https://www.geoinstitute.org/special-projects/idea).

“The goal of the IDEA program is to foster further innovation with proven ERS technology, encourage the development of new technologies, and improve the methods by which the technologies are delivered to projects on the ground. The IDEA program is intended to provide a consistent framework to propose changes to standard practice that owners may take advantage of by expanding ERS innovations in their projects. Towards this goal, the IDEA Program has been developed to provide guidance for three tasks: 1) the technical evaluation of earth retaining systems; 2) the use of reports of evaluations by transportation agencies; and 3) archiving and maintenance of reports of evaluations.”

The “Report of Review” from the IDEA program, along with the submitted document that addressees all of the system’s technical issues, can be obtained from the website https://www.geoinstitute.org/special-projects/idea/evaluation-reports/ or by clicking the button below.

The Greensteep system is now in the application process with the California State Department of Transportation for their consideration as an approved system that will be applicable to their future projects. Such DOT approval will trigger Greensteep’s commercialization.

FUTURE ADDITIONAL INFORMATION

The system is in the final phase of its evolution, so there will be much more information forthcoming on our web site, as it becomes a commercially available system. The Greensteep system employs an in-house developed mobile press and some ancillary equipment for block fabrication and installation. It is expected that in the near future, prototype projects will demonstrate the capacity to fabricate and install on the order of 40 blocks, per press, per day, which translates to 40 x 6 sq-feet, or 240 sq-feet of slope facing production per day.

These upcoming prototype projects will generate the data necessary for accurate cost of production estimates.

We intend to post additional information on this web site, as it becomes available.